High quality styrofoam epp eps mold parts Cr12 steel vent sand casting mould gas vent core box mold core vent

Cr12 steel gas vent Wire cutting core vent styrofoam moulds steam vent China EPS EPP moulds spare parts

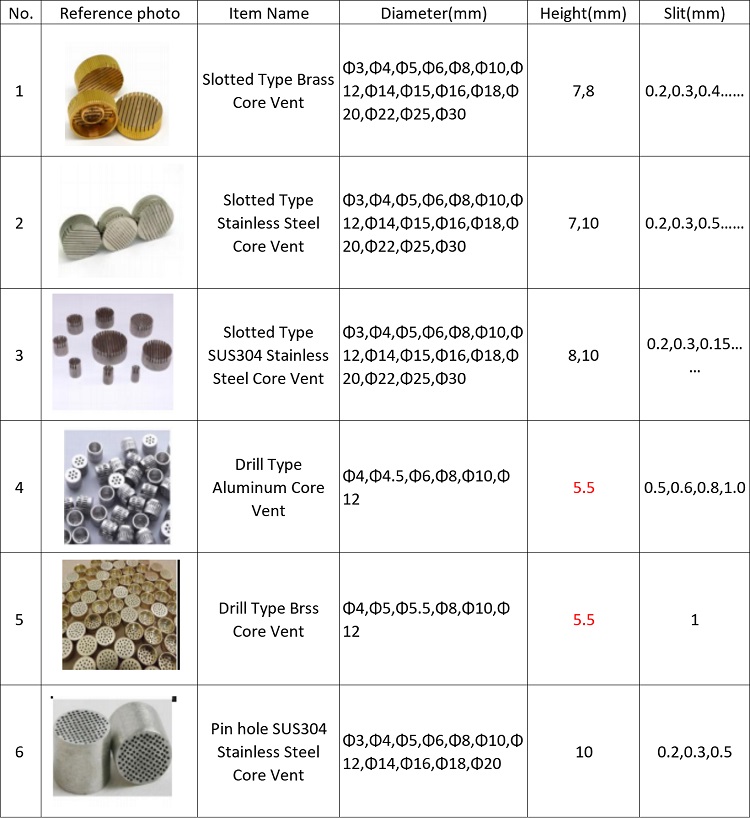

BRASS TAPER SLOT CORE VENTS

Brass core vents are made from a softer metal which makes it easier to remove from the core box. It is also easier to clean and contour.

BRASS PARALLEL SLOT CORE VENTS

Brass parallel slot core box vents vents are made from a softer metal which makes it easier to remove from a core box and clean. Brass parellel slotted vents

can be contoured with the surface of the core box.

STEEL PARALLEL SLOT CORE BOX VENTS

Steel core box vents offer increased resistance to wear, can tolerate higher temperatures and can be used with steel core boxes for uniform heating and cooling.

STEEL TAPER SLOT CORE BOX VENTS

Steel core box vents offer increased resistance to wear, can tolerate higher temperatures and can be used with steel core boxes for uniform heating and cooling.

STANDARD MESH CORE BOX VENTS

Core box vents with a standard mesh screen.

FINE MESH CORE BOX VENTS

Core box vents with a fine mesh screen.

Brass – Screen Core Vents

This brass body vent offers a high venting area with a corrosion resistant, nickel-copper alloy screen.

SUPER CORE BOX VENTS

Super Vents are self-cleaning and feature an opening rate of more than 43%. Using these vents will solve the problem of clogging which can affect the

continuous operation of a core molding machine during no-bake molding. The 43% opening rate (compared to an average of 13% for slotted vents and

30% for screen vents) results in more effective and efficient venting.

ALUMINIUM CORE BOX VENTS

Aluminium core box vents are widely used in Styrofoam moulding applications and give similar advantages to steel core vents

Aluminum – Slotted Core Vents

This slotted-style, aluminum vent is particularly well-suited for use in aluminum molds used in making patterns and Styrofoam packaging.

Also available with a non-stick coating.

Nylon Core Vents

Nylon Vents are injection molded for high precision. These vents provide a ‘non-stick’ surface combined with the toughness of nylon. Ideal for medium to high pressure molding, they are highly recommended for use in blow squeeze machines, v-process, and with cold box and CO2 sand systems.

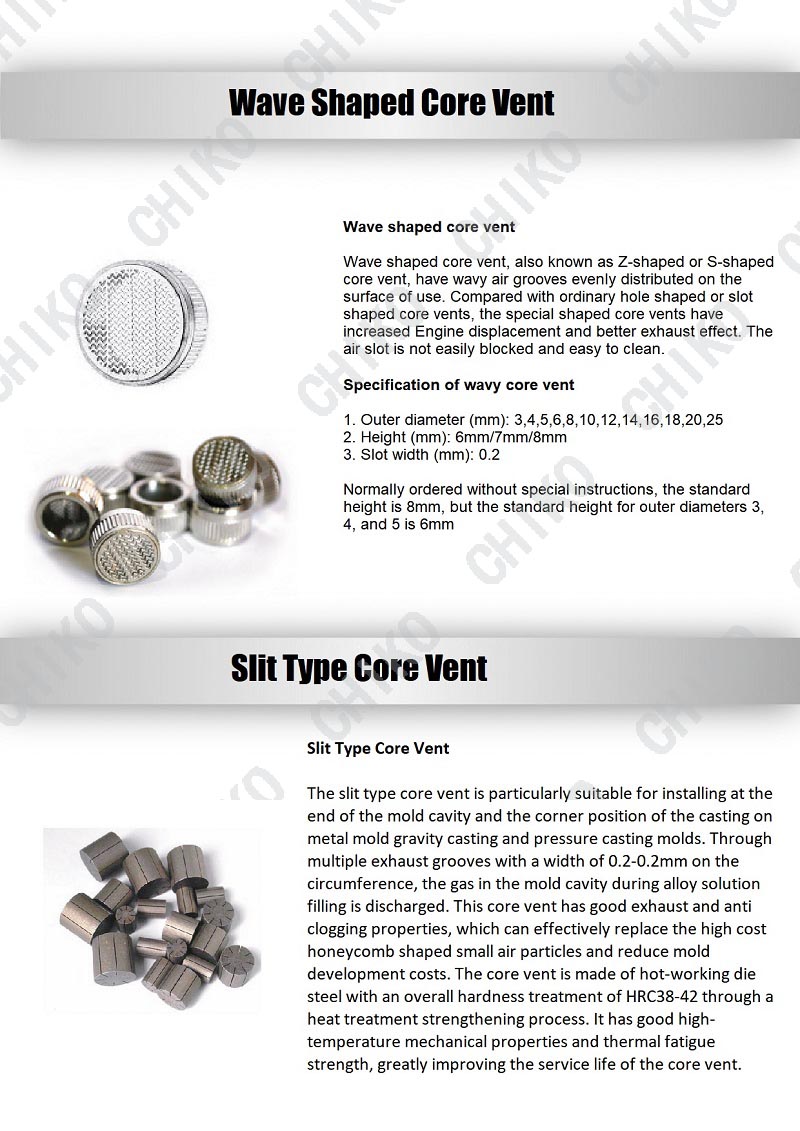

Sintered Vents

Gravity, Low Pressure/Vacuum Casting & Die Casting Applications

Sintered Vents provide an innovative way to decrease molding defects while improving venting efficiency.

Applications

Sintered vents are inserted into molding dies to assure sound castings. They allow the escape of gas and prevent the passage of smelt.

Contact: Gabriel PH

Phone: +86 18665199375

E-mail: info@precision-mold-parts.com

Add: No. 2, 8 Hongye North Road, 138 Industrial Zone, Tangxia Town, Dongguan, Guangdong, China