Icebox Styrofoam Mould Top Upper Cushion Pad EPS Mold Corner Pad Tub Cabinet Foam Packing Aluminum Alloy Mould

Icebox Styrofoam Mould Top Upper Cushion Pad EPS Mold Corner Pad Tub Cabinet Foam Packing Aluminum Alloy Mould

Place of Origin: Guangdong, China

Product Material:Aluminum alloy 6061

Surface treatment:Teflon coating

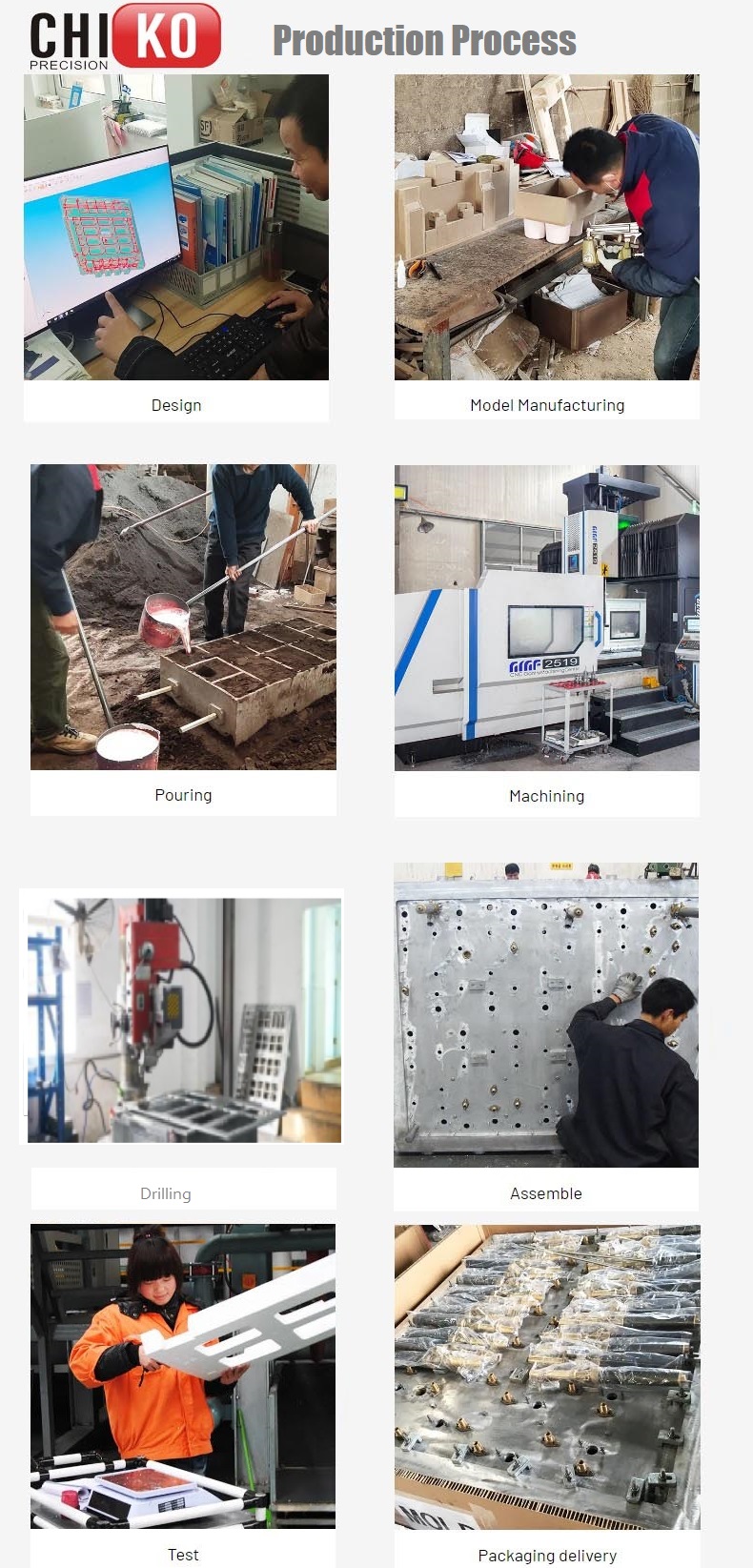

Lead time: Around15-25 days

Product Name:

Icebox Styrofoam Mould,Top Upper Cushion Pad Eps Mold, Aluminum alloy mold

Category:

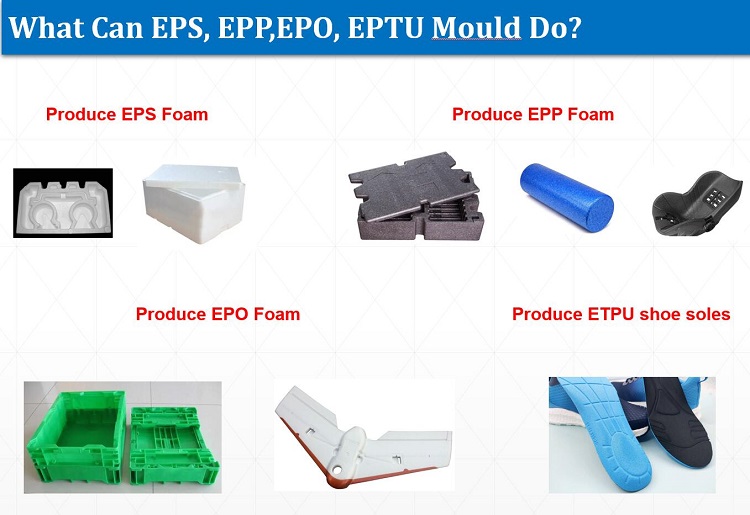

EPS(styrofoam) mold,EPP mold,EPO mold

Used for :

23.6",32",38.5",43",50",55",65",75",85",95" LED TV Packing EPS inside box

Application:

Packing industry, Home appliance,Consumer Electronics,Toys, Furniture, Aeromodelling, Sporting and etc.

Advantage:

It Reduced Weight:

the mould is made of Aluminum, it is much lighter than steel.

Strengthened:

The foam-like structure produced by foaming moulding makes plastic items stronger and more rigid. As a result, products may be more durable and last longer.

Short Lead Time:

only 15-20 days to finish one set of mould.

Improved Thermal Insulation:

Plastic components can improve their thermal insulation capabilities by having a foam-like structure formed by the foaming moulding process.

Reduced Shrinkage:

Gas can be added during the foaming moulding process to help minimize shrinkage, producing more accurate and exact components.

Cost-effectiveness:

This moulding can lead to cost savings since it uses less material, has a faster cycle time, and produces a better product. Due to the decreased weight of the produced plastic pieces, it can also save shipping costs.

Eco-friendly:

Foaming moulding is also environmentally friendly since it uses less material and produces less waste.

Contact: Gabriel PH

Phone: +86 18665199375

E-mail: info@precision-mold-parts.com

Add: No. 2, 8 Hongye North Road, 138 Industrial Zone, Tangxia Town, Dongguan, Guangdong, China